In a context of an increasing attention to ESG reputation of energy Companies, major oil&gas operators are increasing their attention to asset reliability. Well conditions pose environmental challenges due to long-term exposure to corrosive fluids and, especially for CCS operations, the management of well integrity has to be taken into account.

Well integrity risk model

Within this context, Kwantis upgraded a blowout risk assessment system of a major oil&gas operator with the objective to evaluate well integrity during production, gas and water injection, CO2 injection for Carbon Capture and Storage (CCS) and H2 storage operations.

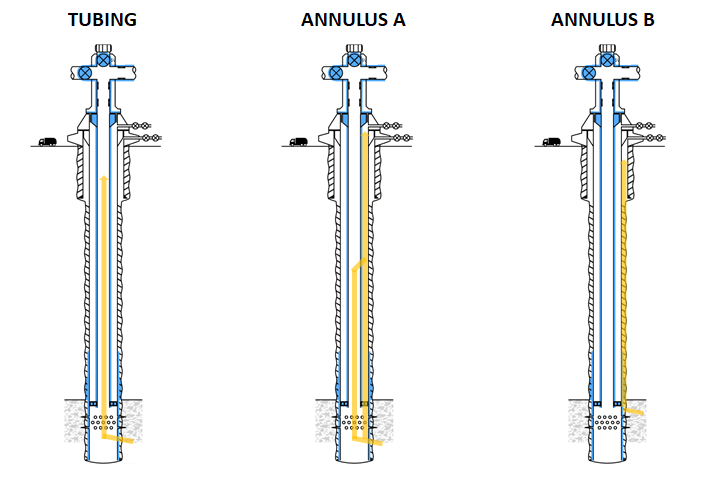

The risk assessment is based on the Fault Tree Analysis approach and probability of well integrity loss is calculated by considering human errors, equipment reliability and testing frequency, as well as annulus pressure conditions. More than 140 blowout scenarios have been included, together with a new cement and tubular degradation model that takes into account the corrosion of tubular materials and the carbonation of cement materials. This model has been integrated to consider the environments specially for H2 and CCS wells where well conditions are particularly severe for material durability.

“An upgrade in operations reliability”

Such upgrade grants an improvement in the system which allows to describe accurately a wider set of operations providing a robust and exhaustive description of each phenomenon occurring on them. Currently these calculations are the answer towards governmental bodies, agencies or top management when asking about well blowout risk exposure.