Talking about time and cost reduction, Non Productive Time prediction represent the best strategy for cost reduction. The huge amount of data coming from the rigsite sensors, combined with big data analytics, will provide a big improvement in operation monitoring, for economic and safety reasons.

Predictive Model for Drilling Problem Anticipation

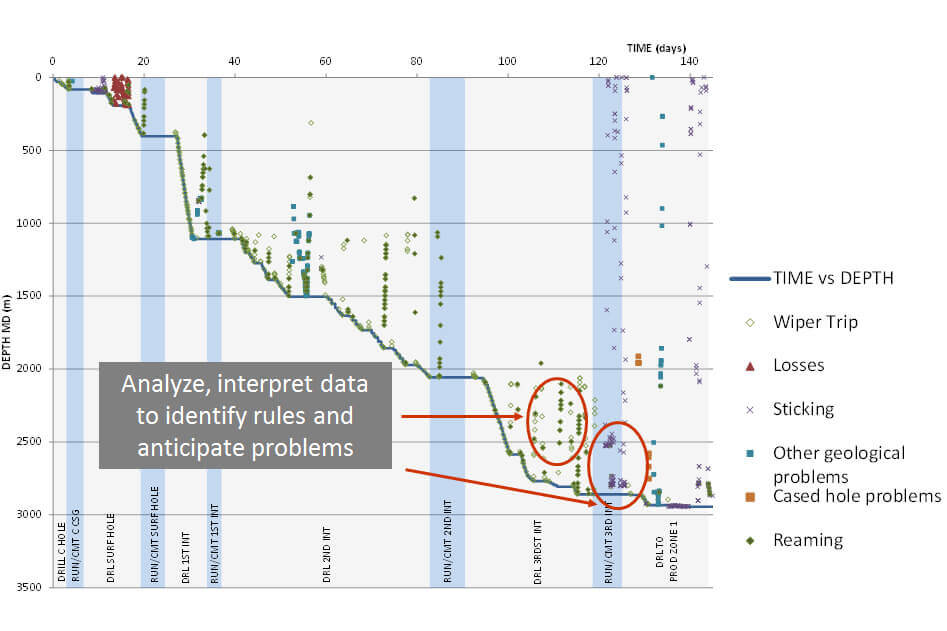

The Non Productive Time prediction is currently one of the most topical issues under study for oil&gas operators. Existing real-time monitoring helps to solve operating problems from remote locations. kwantis is enhancing this real-time monitoring, teaching the system to recognize some trends or patterns and avoid downtime by problem anticipation. Starting from one of the most common and risky well problem (sticking), kwantis is building an Operational Intelligence solution that integrates different data sources, combines them on time/depth bases, and examines and explores them in order to find out some trends or patterns. These patterns will advise about the upcoming issue and therefore create a warning that suggest to adjusting drilling parameters and avoid Non Productive Time.

” kwantis strongly fosters this project because prevention is better than curing”

Once demonstrated the feasibility of this Pilot Project, the advantages of Operational Intelligence could be extended to other well problem events, then applied to both explorative and development and to all wells worldwide.